We at Osona Programació help companies optimise their production. We have created a tailor-made software program following these values:

-

Collaborate

We at Osona Programació S.L collaborate with clients to optimise processes which take place in each of their departments.

-

Integrate

We optimise solutions through cooperative work with your technical staff in a transversal and transparent manner.

-

Assistance

We quickly resolve any issue with high quality solutions. We assist the company every day because we form part of it.

What we do

We at Osprog CREATE the tools to improve management. We make satellite programs to connect with the Enterprise Resource Planning (ERP) systems. We produce software programs, administer applications and provide the most cutting edge technology for your company.

Here are our top products:

-

Efficiency MES

Efficiency MES enables standardisation of processes, equipment and activities to obtain faster benefits in productivity, quality and cost savings in operations. It is an MES application that enhances and boosts production capabilities, covering the main IT needs of a manufacturing plant.

-

SAGE INTEGRATION

Our Efficiency application is completely integrated and homologated with Sage. The integration is totally transparent for the user and functions in real time. Any reference, cost evaluation, work order, etc., created in Sage is immediately available for the application. Similarly, the results for manufacturing, incidents, materials, etc. are processed in Sage.

-

EFFICIENCY CONTROL FOR INDUSTRY 4.0

Automated signal capturing for monitoring and tracking production. The fourth industrial revolution, also known as Industry 4.0, is here to stay. Development of advanced production techniques, new strategies and more efficient management.

-

SOFTWARE FOR LEAN MANUFACTURING

At Osprog we have spent years developing software for Lean departments in the automotive sector, and more recently in other sectors such as food. Our programs make it easier for Lean departments (internal/external) to implement QRM and/or Lean philosophy in companies.

-

What’s more, Osprog has more than 25 years’ experience in the development of applications for the industrial sector with customers spread out all over the world, developing scalable standard products that can be adapted according to customer specifications.

01 Production control

With desktop and web applications and our specialised programming, we plan the work orders and perform real time follow up of the production status.

02 Warehouses

We manage warehouses with the dynamic location system and with real-time stock need requests.

03 Quality

Quality is in everything we do. Furthermore, we manage quality certificates, we identify defective products and predict the unpredictable.

04 Safety

We maintain safety control at the plant level, via evaluation indicators and controls, which allows us to accurately monitor the entire process and prevent accidents.

05 Experience

We’re backed by over twenty years’ experience. We have worked with all types of teams and sectors. We take challenges head-on and provide the best solution.

06 Solutions

We optimise production resources and we improve product quality. We eliminate duplicates and errors which may occur and we reduce bureaucratic processes. We help manage the relationship among suppliers.

SUCCESS STORIES

Our professional experience allows us to cross borders and build projects across the globe. At the European level, our software is present in the UK, Romania, Portugal, Hungary and Turkey. In Asia and Oceania, we work with China, India, Singapore and Australia. On the American continents, we are present in Mexico, Brazil and the United States.

Blog

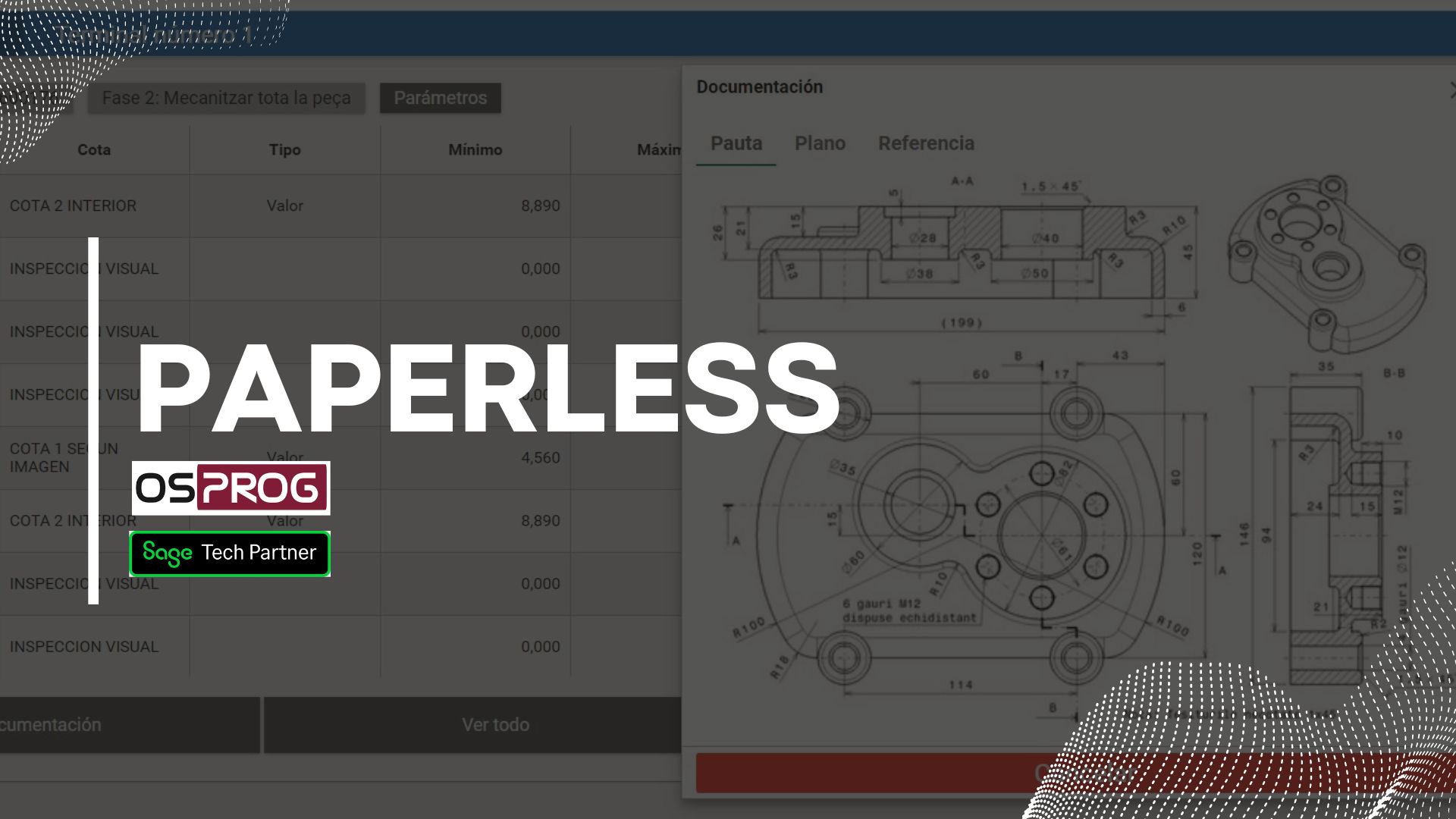

PAPERLESS RELACIONADO AL EFFICEINCY MES

Sí, el término “paperless” se refiere a la transición de un entorno de trabajo basado en papel a un entorno digital, donde se minimiza o elimina el uso de documentos impresos. En el contexto de una fábrica de producción, la...

MÓDULO CALIDAD DE OSPROG

El módulo de calidad en el Sistema de Ejecución de Manufactura (MES) de OSPROG presenta una serie de características clave que contribuyen a la gestión efectiva de medidas y comprobaciones durante la producción: En conjunto, este módulo de calidad ofrece...

Clients

Would you like some more information?

Contact us and we will help you find the right solution for your company.